james_edward

-

Posts

461 -

Joined

-

Last visited

Posts posted by james_edward

-

-

They do let me out occaisionally. :)

EG

Hello EG, next time you drop by you should bring the gasman with you, I've read that he also loves epi's

-

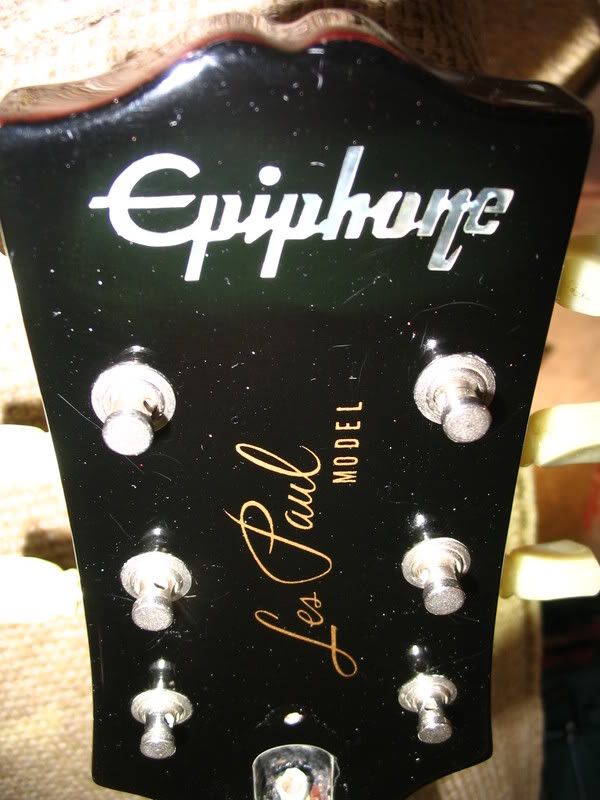

So it seems that this headstock is exclusive to the '89 LP. Or, if its an Epi LP with this headstock its an '89, whichever way you you want to say it. Right?? I know that it was used on the semi-hollows but I think the logo on those had the typical Epi slant/tilt, whereas the LP's logo was straight across. Someone with that era Samick semi can clear that up real quick........J

Here's the headstock from a white Samick custom Lp, 1989 model

-

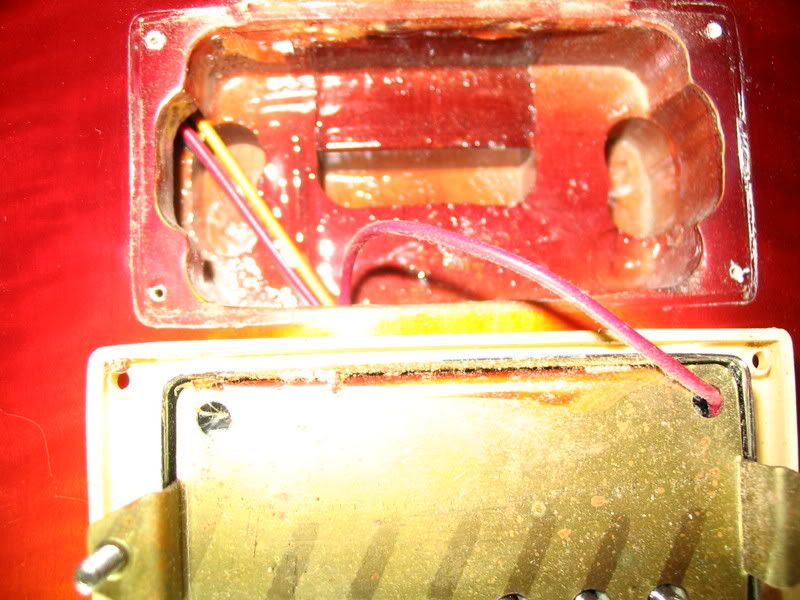

Just going back over old posts and came across this one. SH's 1989 catalog is obviously correct, however, on the ehow.com/about Samick site it states that LP's were not produced there until the mid '90's. Don't understand why there's confusion on this point but that just adds, or detracts, mojo to the guitar. All in all, I have mine and being that I have no S/N I am comfortable saying that its an '89 with a dark cherryburst. Still plays great and as I've stated before if I had to sell the entire stable this would be the last to go, including the '88 pre-historic '59 RI Gibby. The only identifying mark on it is the number 6 or 9 in the bridge pup cavity shown in the pics. I don't know about the 17 degree headstock being accurate on the Epi though. I think we had a way to measure that on the old old forum but I never did try to measure it. Whatever, its a good guitar and I'm glad I have it..............J

www.ehow.com/about_5427510_early-samick-lp-guitars.html

I've seen a few of the Korean LP's with this headstock, including a white custom and a couple of bursts, every one was a 1989 model.

-

Even if it doesn't sound so good, a little investment in electrics and I'm sure it'll be a very good guitar.

-

So, on that tailpiece the axle or pivot shaft is also a torsion bar type spring, the spring is pinned to the body on 1 side, pinned to the “floating” part and free to float in the other socket of the body.

Your only problem is if those pins are a “no drift” type pin (in other words you can only see one side of the pin – where the pin is punched into a hole that doesn’t go right through).

Turn it over and if you can see both side of the pins you’re doing fine – go to your local hardware store and spend a few dollars on a pin punch, or as we call them in Canada a pin drift, of the correct size.

Drop some oil over the pin locations some time before you’re ready to work – support the piece around the pin location as you punch it, but leave a hole in the support piece for the pin to fall into – and punch the pins out – flip the piece and re-assemble.

That’s my take on it anyway…

Is my Epiphone Les Paul Custom Alpine White is real?

in Epiphone Electrics

Posted

One picture would have been good enough - there are no legit EE Epi's with two different font sizes in the serial number.

The most faked Epi is the LP Custom, mostly in black or white, and almost all EE07 serial number.

This is the first fake EE08 I've seen because most of the scammers had realized their mistake by 2008.